PRODUCTION

Expert in agricultural products, Velibaba Spice produces goods such as thyme, bay leaf, and sage. It does not compromise its naturalness and purity during processing by selecting the most appropriate raw materials in accordance with the standards. It prioritizes food safety and quality control processes at all stages of production, besides recording every step starting from the field in order to ensure traceability, which is an indispensable step in the food industry. Additionally, upon request, it can send its products subject to steam sterilization.

RAW MATERIALS

Selecting the raw materials very professionally, Velibaba Spice provides direct quality and trust with this approach.

The acceptability of the raw material is based on the compatibility of values such as pesticides, PAs (Pyrrolizidine alkaloids), and essential oil amounts. Physical characteristics like color and smell are also crucial acceptability criteria.

Controlled sieving and sorting processes have a great effect on the final product. As a result, this process, which begins with raw materials, is finalized carefully.

PRODUCTION

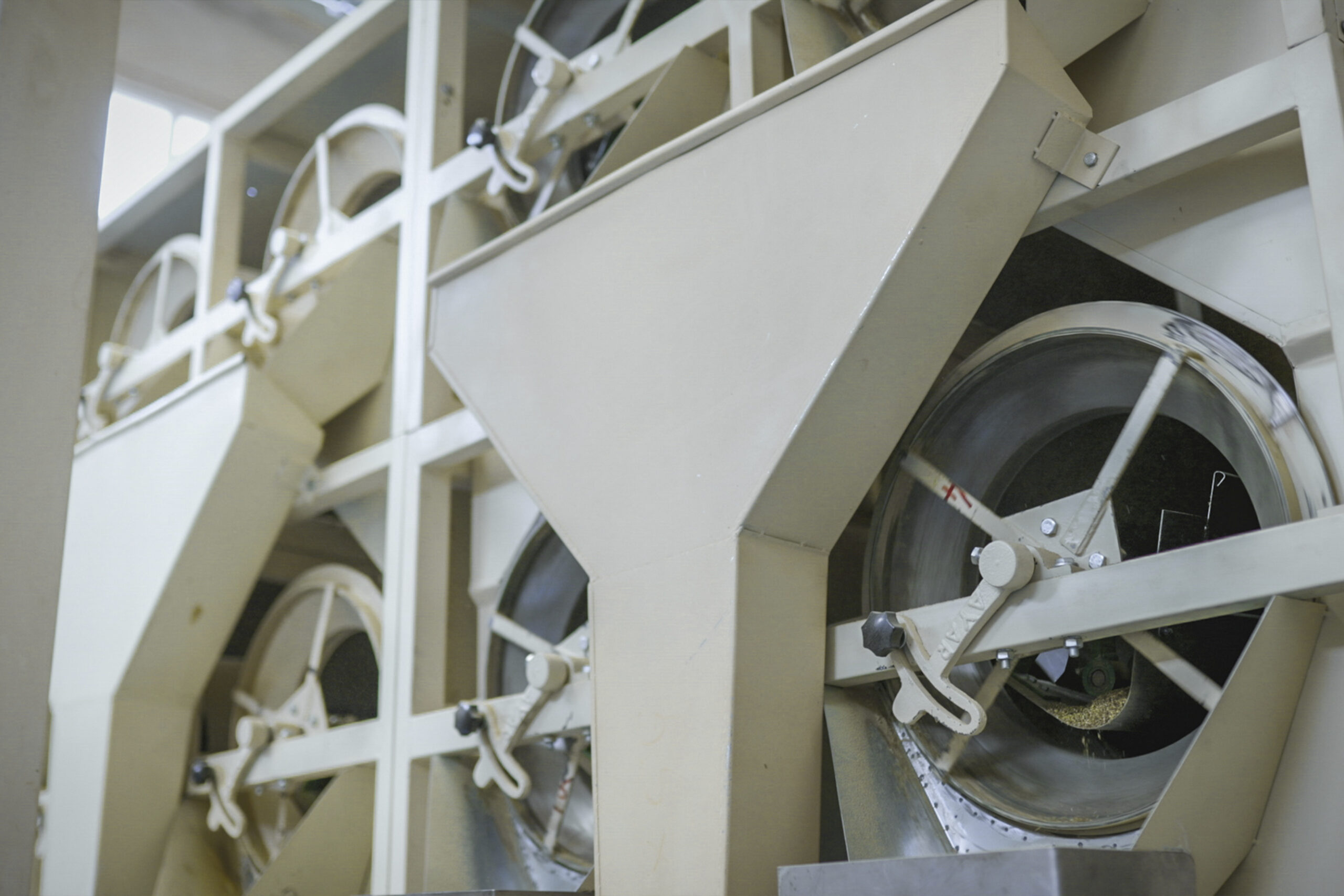

During processing, the raw material is gradually sieved on fully automatic lines until it reaches the final product calibration.

Thanks to the sieving and sorting processes, the final product is separated from unwanted components such as stems, stones, and dust and brought to the appropriate dimensions.

Semi-finished and final products, which can be processed in different bulk densities, can be optionally sent in Kraft paper bags, PP bags, PE bags, and carton boxes.

PRODUCTION

During processing, the raw material is gradually sieved on fully automatic lines until it reaches the final product calibration.

Thanks to the sieving and sorting processes, the final product is separated from unwanted components such as stems, stones, and dust and brought to the appropriate dimensions.

Semi-finished and final products, which can be processed in different bulk densities, can be optionally sent in Kraft paper bags, PP bags, PE bags, and carton boxes.